Plate heat exchanger

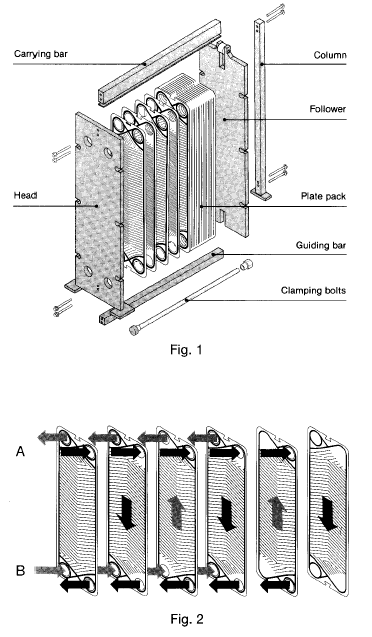

The plate heat exchanger is composed of a fixed pressing plate, a movable pressing plate, an upper beam, a lower beam, a tail column, and a clamping bolt. A plurality of plates are clamped between the fixed clamping plate and the movable pressing plate.

Each plate is fitted with a pad to form a closed parallel channel system. The medium can alternately flow into different channels through this system. (eg Fig.1)

Plate group

The gasket is tightly adhered to the groove of the plate to ensure effective sealing of the fluid medium and the atmosphere. The two gaskets are sealed between different media, and there are drainage grooves between the two seals, so the two media are not May be mixed.

In the set of plates, the angle of rotation between adjacent plates is 180°, so in this closed parallel channel system, the medium can alternately flow into different channels. (Figure 2)

Intermediate partition

If a plurality of media in the plate heat exchanger are operated at the same time, an intermediate partition is required.

The intermediate partition is provided with a conversion block to form a connection of different parts. A conversion block can be set up with two connection lines connecting two different parts of the plate heat exchanger.