Product Introduction

M Series Gaskets & Plates Replacement For Plate Heat Exchanger

Model List as below.

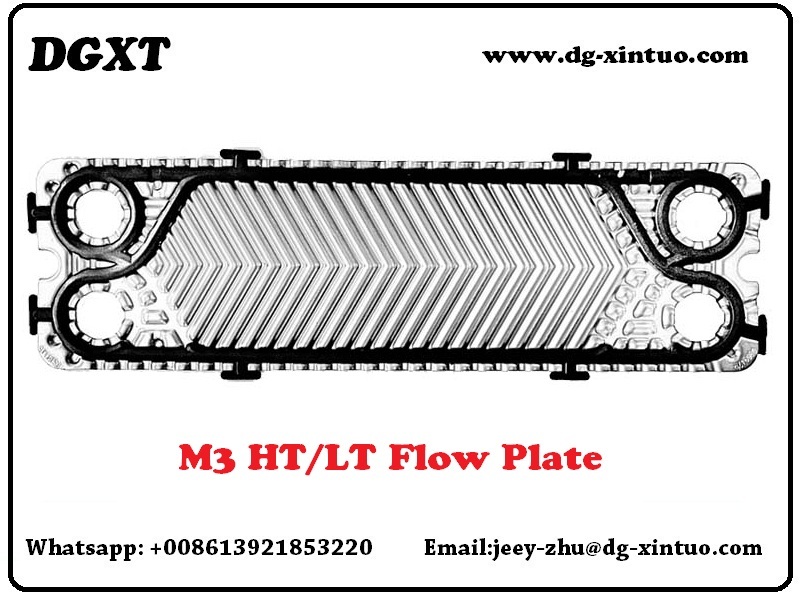

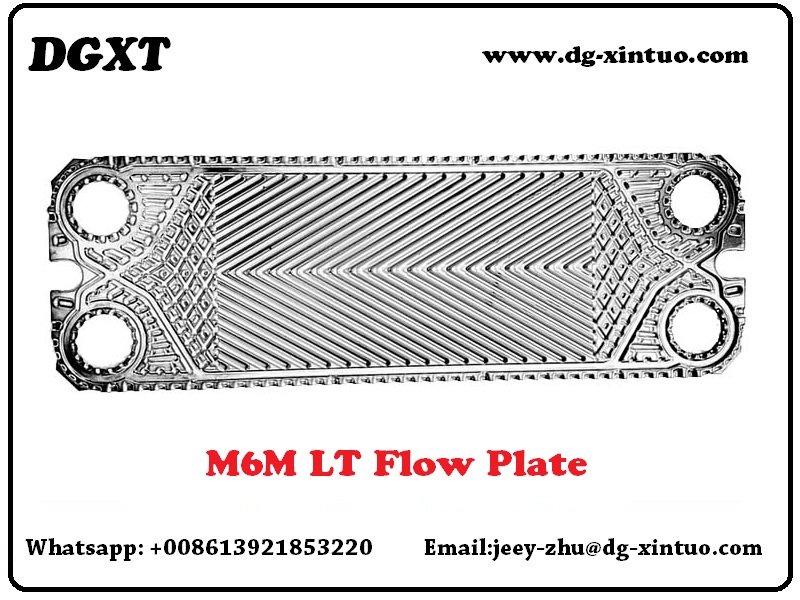

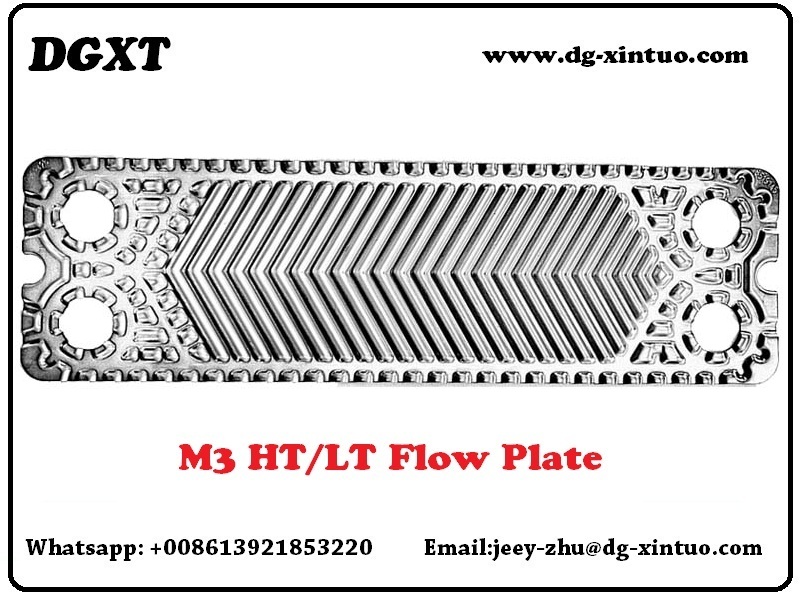

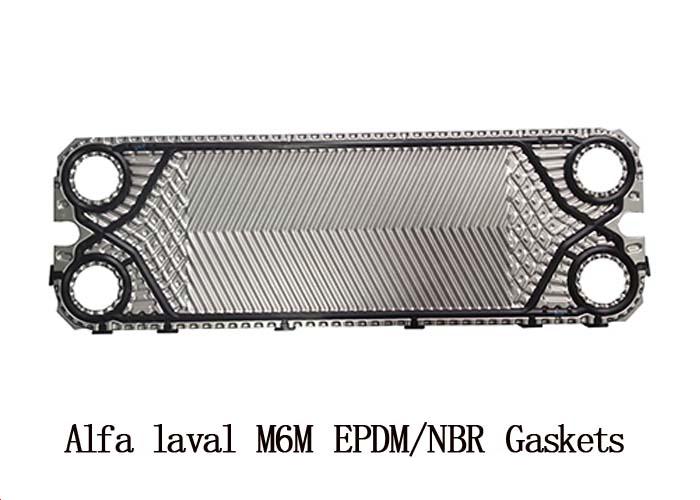

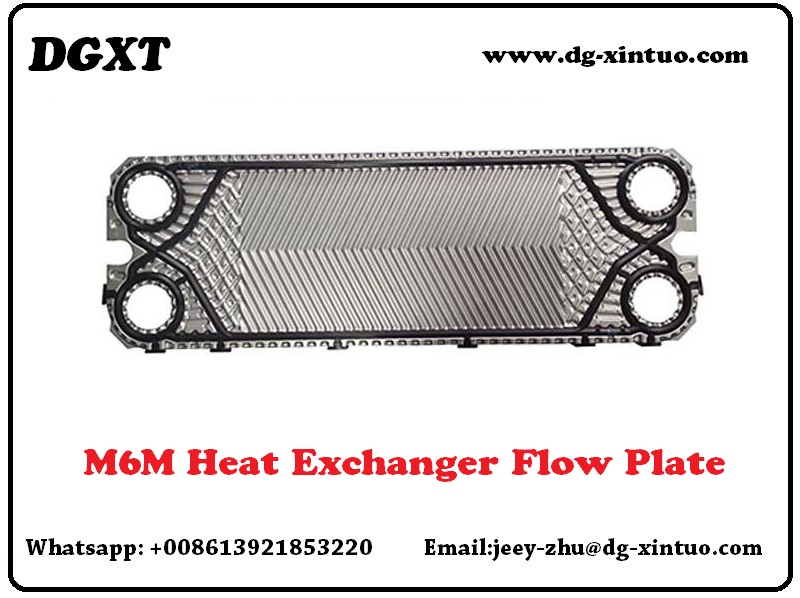

| M3 | M6M | M6B | M6MX |

M10B |

M10MX |

M15B |

|

M15M |

MX25M |

MX25B |

M30 | MA30S | MA30M | M6MW |

|

M3-FG |

M3-X |

M15-MFM |

M15-MFD |

M15-MFG |

M15-BFG |

M15-BFD |

|

M15-BD |

M10-MFG |

M10-MFD |

M10-MFM |

M6-MFG |

M6-MFD |

M6-MXL |

|

M6-MXR |

...... | M10MX |

|

|

|

|

Gaskets Information:

Gasket - materials

• The choice of rubber material depends on

– Fluids - chemical attack or not

– The combination of temperature and pressure

• Rubber materials change properties due to

– Time - the rubber relaxes

– Temperature - the rubber deteriorates

– Hardening by attack of oxidising agents (e.g., oxygen in air)

– Swelling or softening by absorption of chemicals in the fluids

• Common gasket types

– Nitrile– EPDM– FKM

• Nitrile

– Inexpensive standard material up to 130°C

• NBR P (performance) up to 130°C

• NBR B (base) inexpensive for lower temperatures

– Application related NBR qualities

• NBR HTF - food grade for high temperatures

• NBR LT - for low temperature in refrigeration applications

• H NBR (hydrogenated) for duties where normal NBR swells and for higher temperatures, more expensive

• EDPM

– Standard material up to 160 °C

– Standard EPDM qualities

• EPDM for glued gaskets (“Crushing resistant”)

• EPDMC for clip-on gaskets at high temperature

• EPDMCT as above but for thin gaskets in models with low

pressing depth (1.5-3 mm)

– Application related EPDM qualities

• EPDMF - food grade

• EPDM AL for increased pressure resistance in certain chemical

duties where normal EPDM swells

• FKM, Fluorocarbon rubber

– Often called Viton (DuPont trade name)

– Used for aggressive chemical compounds

• Sulphuric acid

• Aromatic organic compounds

• Chlorinated organic compounds

– Two different qualities used

• FKM G

• FKM S

• Other types are Neopren, Hypalon, Chloroprene, etc.

Gaskets- sealing lifetime

Product

• Gasket material

• Fastening

– Glue or glue-free

– Type of glue

• Gasket geometry

• Gasket groove

• Alignment of plate pack

Duty

• Operating temperature

• Operating pressure

• Media

• Type of operation

continuous / cyclic

• Cleaning methods &

chemicals

• Opening frequency

• Maximum temperature in CAS and product manual,

for example,

– NBR up to 130ºC

– EPDM up to 160ºC

⇒ Gives about 1 year lifetime

When no chemical attack takes place

• Rule of thumb:

– 10ºC lower than max temperature

⇒ 2 years lifetime

– 10ºC above the max temperature

⇒ 6 months lifetime

• Temperature

– Considered in CAS

– Selects a gasket which gives minimum 1 year lifetime

at the design temperature

– Manual check if other gasket is needed to get longer lifetime

• When aggressive fluids are present

– Gasket Selection Guide programme

– Ask the customer

– Contact the Market Segment

– Testing with small test-gaskets in the customers process

Plate Information:

Plate - materials

• Standard materials and thicknesses

– AISI 304 (stainless steel)

• Usually 0.4 or 0.5 mm thickness

• Cheapest possible solution

– AISI 316 (stainless steel)

• Always 0.5 and 0.6 mm

• Some with thicker plates (high-pressure applications)

– 254 SMO (high-alloy stainless steel)

• Usually in 0.6 mm to allow stock-keeping

– Titanium

• Always 0.5 and 0.6 mm

• Some with thicker plates (high-pressure applications)

• Some PHEs with 0.4 mm (low-pressure applications)

– Alloy C-276 (Nickel alloy)

• Usually in 0.6 mm to allow stock-keeping

• Standard materials and typical uses

– AISI 304

• Typically in clean water-water duties

• Example, up to 50 ppm chlorides at 50°C

– AISI 316

• Typically in water-water duties

• Example, up to 250 ppm chlorides at 50°C

– 254 SMO (high-alloy stainless steel)

• Many uses including high-chloride water-water duties

• Example, up to 6000 ppm chlorides at 50°C

– Titanium

• Most frequent use is for sea water (3.5% chlorides)

• Example, up to 130°C in sea water

– Alloy C-276 (Nickel alloy)

• Most frequent use is for concentrated sulphuric acid up to 90°C

• Common exotic materials

– Not always on stock

– Check with Supply Unit before quoting and confirm before order

– 904L is an alternative to 254 SMO in some applications

– Nickel 200/201 is mainly for sodium hydroxide production

– Titanium Palladium

• For sea water at high temperature (>130°C)

• For high concentrated chloride brines at high temperature

– Alloy G-30 is used in the sulphuric acid application (scrubber)

– Alloy D-205 is exclusively for concentrated sulphuric acid >90°C

• Many more are used less frequently on a case-by-case basis

How to know which plate material to use?

– Application Manual

– Contact the Market Segment

– Ask the customer

– Testing with small test-pieces in the customers process

M-serie PHEs

• Basic objectives were

– To replace the A-serie with a smaller number of PHE types

– To supply each type with the various plates needed

– To design all plate of a given M-type for same raw sheet material

• Advantages

– Less inventory and scrap

– Shorter delivery time

– Reduced tooling investment

– Minimised administration

M-serie PHEs

• Features implemented with the M-serie

– Always parallel flow

– Chocolate pattern

– Corner guidance on M10 and smaller models

– Sheet thickness down to 0.4mm

– Glue free gaskets

– Improved pressure and temperature performance

• To a large extent the M-serie has been very success

• We are almost ready with replacing the A-serie

• No time to rest

⇒ Move ahead with the future PHE range