Brief introduction of plate heat exchanger

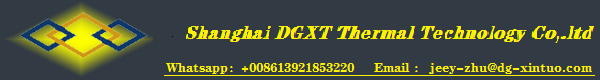

It can be divided into plate heat exchanger/plate cooler/plate evaporator/plate condenser according to their functions.

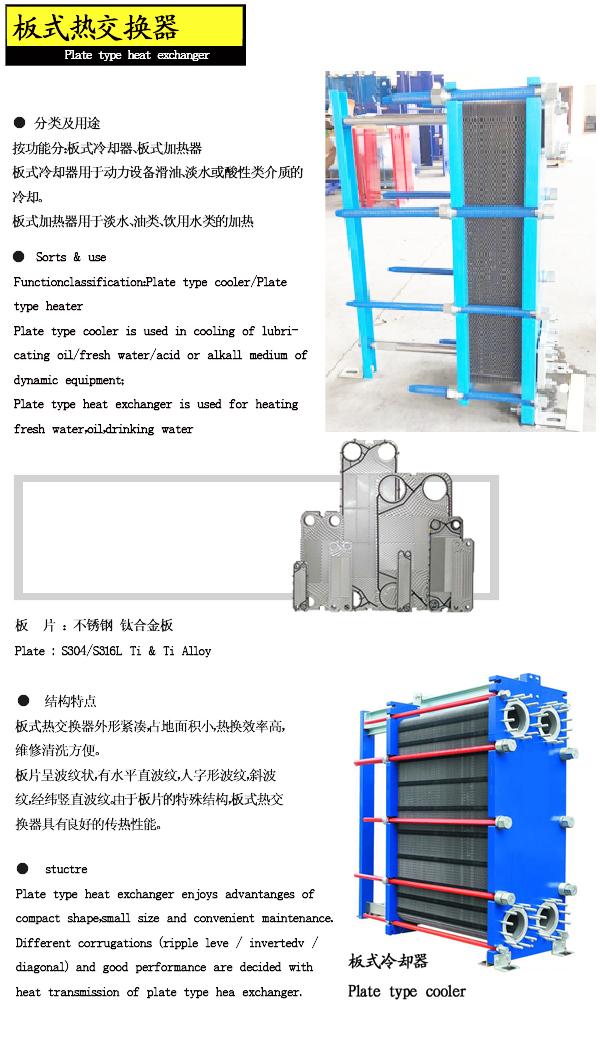

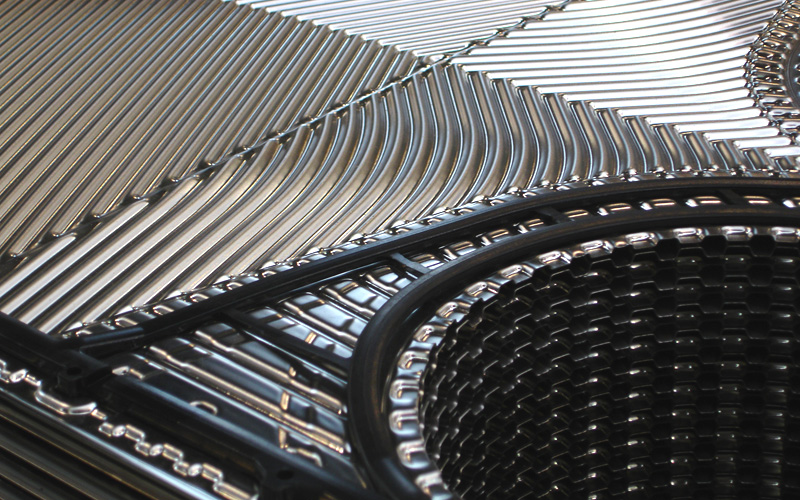

Plate heat exchanger is a kind of high-efficiency heat exchanger made of a series of corrugated metal sheets. A thin rectangular passage is formed between the plates to exchange heat. Plate heat exchanger is an ideal equipment for heat exchange between liquid and vapor. It has the characteristics of high heat transfer efficiency, small heat loss, compact and light structure, small floor area, wide application and long service life. In the case of the same pressure loss, the heat transfer coefficient is 3-5 times higher than that of the tube type heat exchanger, and the area is 1/3 of the tube type heat exchanger, and the heat recovery rate can be as high as 90%.There are two main types of plate type heat exchangers: frame type (detachable) and brazing type, which are mainly composed of human shaped corrugated plates, horizontal flat corrugated plates and three kinds of plate plates.

Plate cooler is used for cooling lubricating oil, fresh water or acid medium of power equipment.

Plate heater for heating fresh water, oil and drinking water

Structural features:

Plate heat exchanger has compact shape, small floor area, high heat exchange efficiency, easy maintenance and cleaning.

Plates are corrugated, with horizontal straight corrugated, herringbone corrugated, oblique corrugated, vertical warp and weft corrugated. Because of the special structure of plate, plate heat exchanger has good heat transfer performance.

Why Choose Plate heat exchanger machine?

Compared with traditional shell-and-tube evaporator and condenser, using plate-type evaporator and condenser bring unimaginable benefits. Not only covering less space, saving valuable space, but also reducing investment costs and maintenance without sacrificing reliability and security. On energy saving, plate-type evaporator and condenser can carry on counter-current heat transfer evaporation, closing the temperature difference of two ends. Whereas, shell-and-tube evaporator can only carry on cross heat transfer, so that make the heated steam reduced.

1.High efficiency of thermal conduction

The heat transfer coefficient of plate-type evaporator with special corrugated designs which producing high intensity turbulence has been improved greatly, comparing to shell-and-tube evaporator. The plate-type evaporator is particularly effective in high concentration and high viscosity, and can operate in the temperature difference only 3- 5℃. Steam heat pumps need to be used in tube - shell evaporators, and the secondary steam ejection ratio is very low, only 1:0.5. Because the least temperature difference of first effect evaporation of shell-and-tube evaporator need to be maintained at 15℃, it means the temperature of the steam into the shell-and-tube evaporator need to be at higher level, and can only pump small amount of low temperature of secondary steam. Whereas, the steam ejection ratio can be maintained at 1:1.25 when using plate-type evaporator, and it saves steam consumption a lot.

2. Less scale and convenient maintenance.

The high intensity turbulence in the whole plate not only reduces the scale, but also make it easy for chemical cleaning efficiently. Because of the less retention volume, it only needs few detergent compared with shell-and-tube evaporator. The flexible design of the plate-type evaporator means it is easier to inspect the surface of the thermal conduction, and it can be cleaned by mechanical method which is only removing the fasten bolts and loosening the pressing plate.

3. Expand capacity easily

It is one of the most popular feature of plate-type evaporator that you can just add or remove the plate group based on the current frame if you want to expand or reduce the capacity, and it is the major advantage compared to shell-and-tube evaporator which has the fixed capacity when installing

4. Improve the quality of the products

The very low retention means that at any given time, there is almost no product left in the evaporator of the plate-type evaporator. It is a big advantage to heat sensitive products if products stay when evaporating in a short time. It also allows for quick start and shut down with very little waste.

5. Save users input costs

The unique design of plate-type evaporator and plate-type condenser have higher thermal efficiency compared to traditional shell-and-tube facilities, it means the required heat exchange area is greatly reduced. Therefore it is very economics to use plate-type evaporator and plate-type condenser, especially need to use the special metal such as SMO, Ti, Nickel and Nickel Alloy, and Hastelloy.

6. Save space and Save installation budget

It can be seen clearly from the below schematic diagram, it is a triple effect evaporation system device, and the plate-type evaporator and plate-type condenser can save installation charge and save space greatly compared with traditional devices.