Product Introduction

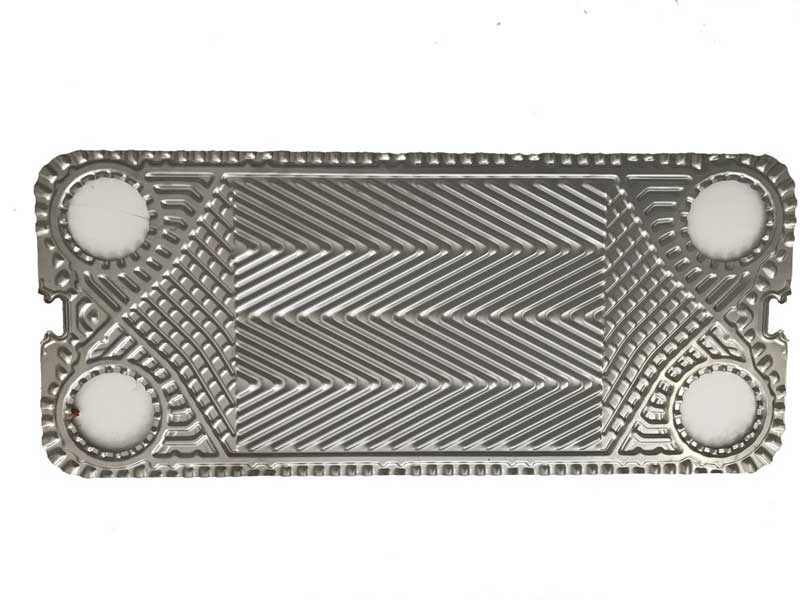

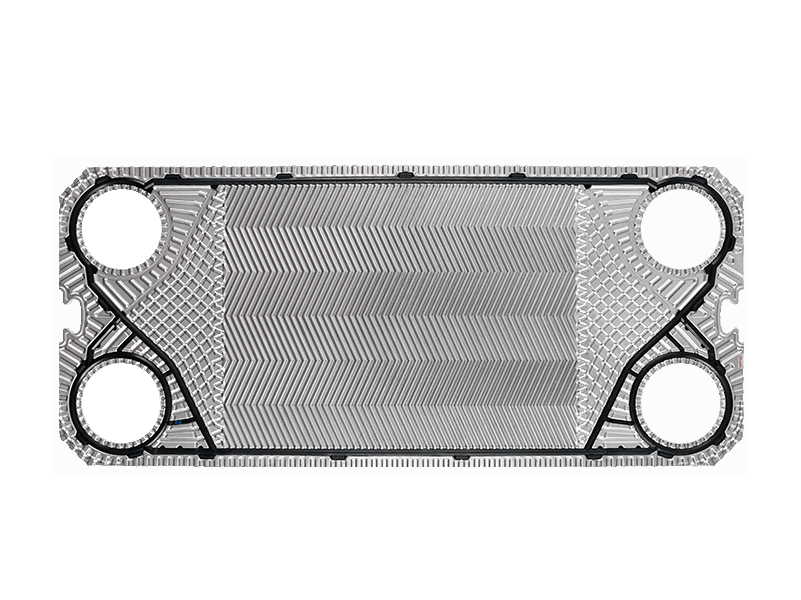

Sondex plate heat exchanger plate characteristics:

1. Each type of plate has been carefully designed and rigorously tested.2. The plates of each specification are divided into two types: big herringbone plate (TL) and small herringbone plate (TK). The heat transfer efficiency of hard plate is high, the fluid resistance is large, the heat transfer efficiency of soft plate is low, and the fluid resistance is small. The passage of plate heat exchanger can be a single soft plate passage, a hard plate passage and a mixture of the above passages. The optimum design of heat exchanger is obtained by scientific channel proportion.

3. SONDEX plate heat exchanger adopts the same side flow, because the design of diversion zone is adopted at the inlet and outlet of plate, that is, the groove design of chocolate Island zone at the outlet of corner hole. The general linear guide groove only distributes the fluid uniformly on one side. The chocolate Island groove design can balance the difference of flow resistance in each channel, and make the fluid distribution between the two sides of the plate relatively uniform. Even the wider plate can make the fluid uniformly distribute between the plates. The traditional plate heat exchanger with the same side flow has been fundamentally improved, because of the difference of temperature distribution along the plate due to the different fluid distribution state and flow dead angle, the adverse effect of the decrease of heat transfer efficiency has been brought about. In addition, this part of the area of the diversion zone also participates in heat transfer, which improves the heat transfer area of SONDEX plate heat exchanger. Margin;

4. Because the above design of chocolate Island diversion zone ensures the uniform distribution of fluid between plates, SONDEX adopts the same side diagonal flow form, which is more convenient for users to take over.

5. International advanced design and production technology make SONDEX plate heat exchanger the best cost-effective product.

6. All the plates of SONDEX plate heat exchangers in the world come from 6 hydraulic presses of SONDEX factory in Denmark. One of them has a capacity of 20,000 t. It is the largest hydraulic press in Europe and is specially used to process large plates with DN400 or more. Because of the large capacity of the press and the advanced stamping technology, every SODNEX sheet is very flat and there is no stress and deformation at all. The surface roughness of stamped sheet is the same as that of the original sheet, which has high quality uniformity. SONDEX sheet fully meets the quality requirements of sheet in food and health industry. It reduces the friction resistance of the fluid, is not easy to scale and pitting corrosion, and ensures the stable and efficient operation of SONDEX heat exchanger.

7. The difference of fluid temperature distribution along the way is caused by the different body distribution and flow dead angle, which leads to the adverse effect of the decrease of heat transfer efficiency. In addition, this part of the area of the diversion zone also participates in heat transfer, which improves the heat transfer area margin of SONDEX plate heat exchanger.

8. Because the above design of chocolate Island diversion zone ensures the uniform distribution of fluid between plates, SONDEX adopts the same side diagonal flow form, which is more convenient for users to take over.

Plate Heat Exchanger Material:

| Plate matrial | Adapt Liquid |

| Stainless steel(304、316) | Pure water、stem water、Edible oil、mineral oil |

| 钛及钛钯(Ti、Ti-Pa) | Sea water、Salt water、Salt compounds |

| 20Cr、18Ni、6Mo(2455Mo) | Dilute sulfuric acid, dilute sulfate, organic water solution |

| 镍(Ni) | High Temperature and High Concentration Caustic Sodium |

| HASTELLOY合金(C276、D25、B2G) | Concentrated sulfuric acid, hydrochloric acid and phosphoric acid |

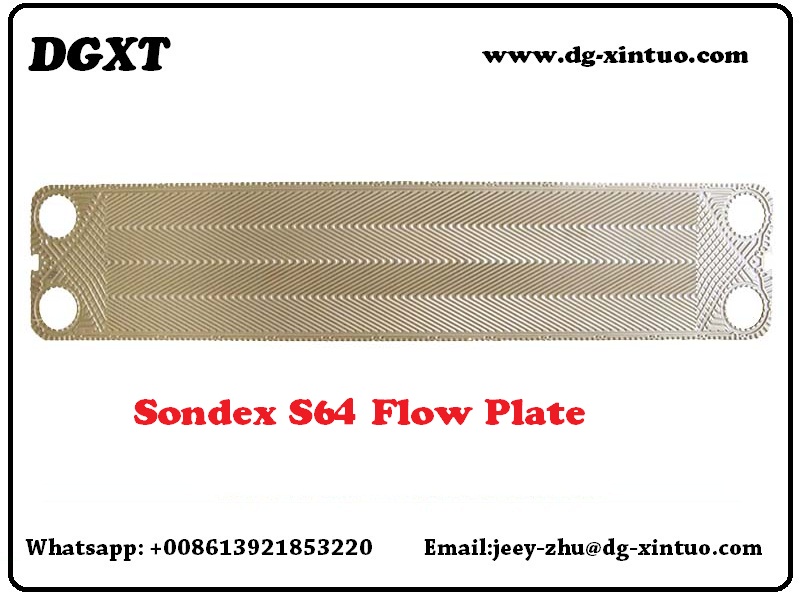

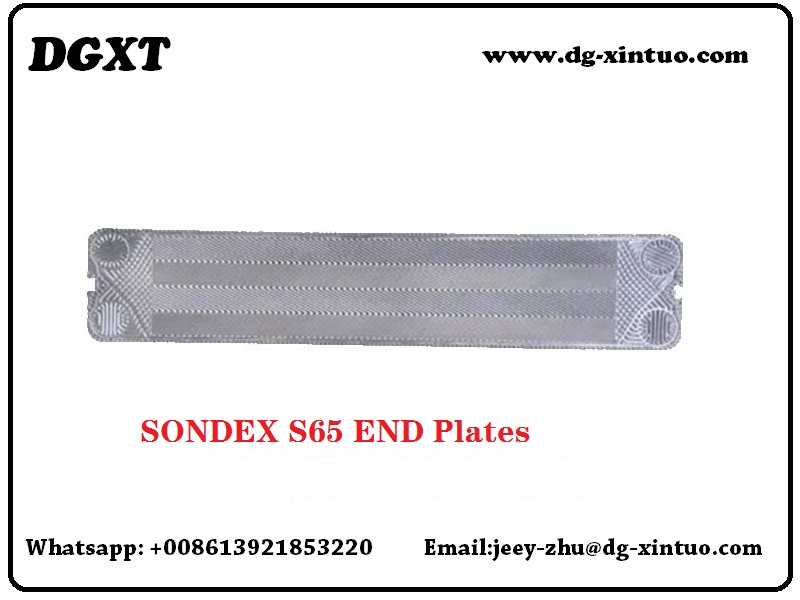

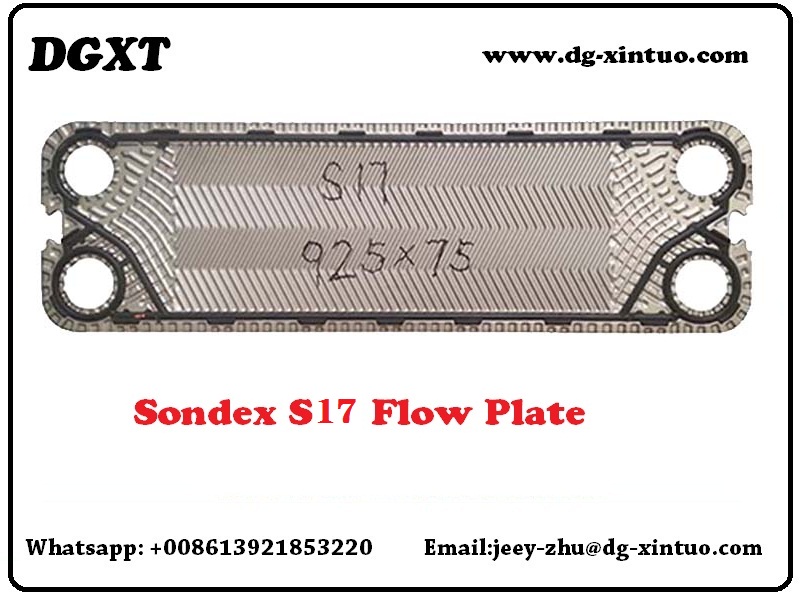

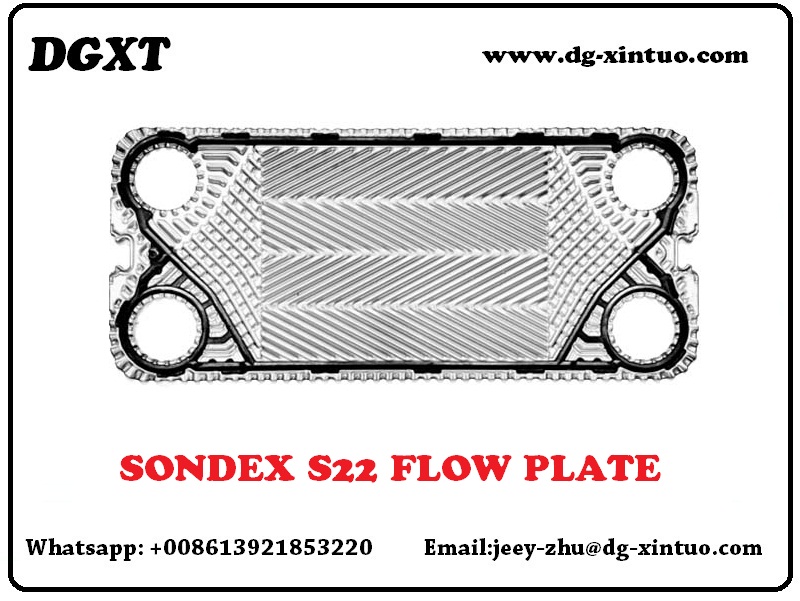

Sondex Plate Type:

| S4A | S7A | S14A | S20A | S7 | S20 | S16B |

| S8A | S9A | S19A | S31A | S17 | S21 | S22 |

| S21A | S22A | S37 | S41 | S41A | S42 | S42A |

| S20A |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| S43 | S63 | S43H | S43A | S65 | S100 | S47 |

| S64 | S81 | S121 | S188 | S81 | S62 | S86 |

| S110 | S113G | S201G | SF123 | SF160 | S130 | SFD13 |

| SFD22 | SFD23 | SFD35 | S113 | S145 |

|

|

Sondex PHE Model:

| Sondex/PHE Specification | |||||

| Detachable Sondex plate heat exchanger specification | |||||

| Model | Connection | surface/plate | Plate | QMAX | Surface max |

|

|

DN | ㎡ | No. | T/H | ㎡ |

| S7 | 50 | 0.07 | 76 | 40 | 5 |

| S14 | 50 | 0.15 | 427 | 40 | 59 |

| S17 | 50/65 | 0.19 | 609 | 40 | 100 |

| S18 | 50/62.5 | 0.19 | 609 | 65 | 115 |

| S21 | 100 | 0.22 | 698 | 180 | 146 |

| S22 | 100 | 0.26 | 538 | 165 | 118 |

| S41 | 150 | 0.45 | 670 | 380 | 274 |

| S42 | 150 | 0.46 | 532 | 360 | 223 |

| S62 | 150 | 0.68 | 670 | 380 | 415 |

| S43 | 200 | 0.46 | 695 | 700 | 300 |

| S65 | 200 | 0.68 | 695 | 700 | 450 |

| S100 | 200 | 1 | 695 | 700 | 695 |

| S130 | 200 | 1.3 | 695 | 700 | 900 |

| S80 | 300 | 0.8 | 930 | 1600 | 744 |

| S81 | 300 | 0.84 | 930 | 1600 | 750 |

| S120 | 300 | 1.2 | 930 | 1600 | 1115 |

| S188 | 300 | 1.88 | 930 | 1600 | 1750 |

| 300 | 1.88 | 930 | 1600 | 2210 | |

| S250 | 300 | 2.51 | 930 | 1600 | 2334 |

| S200 | 500 | 2.06 | 930 | 4000 | 1860 |

| The Table are Sondex Commonly type Pressure Up to 2.5Mpa | |||||

| Frame type:IS、IT、FT、IG、FS、FG、IC | |||||