Product Introduction

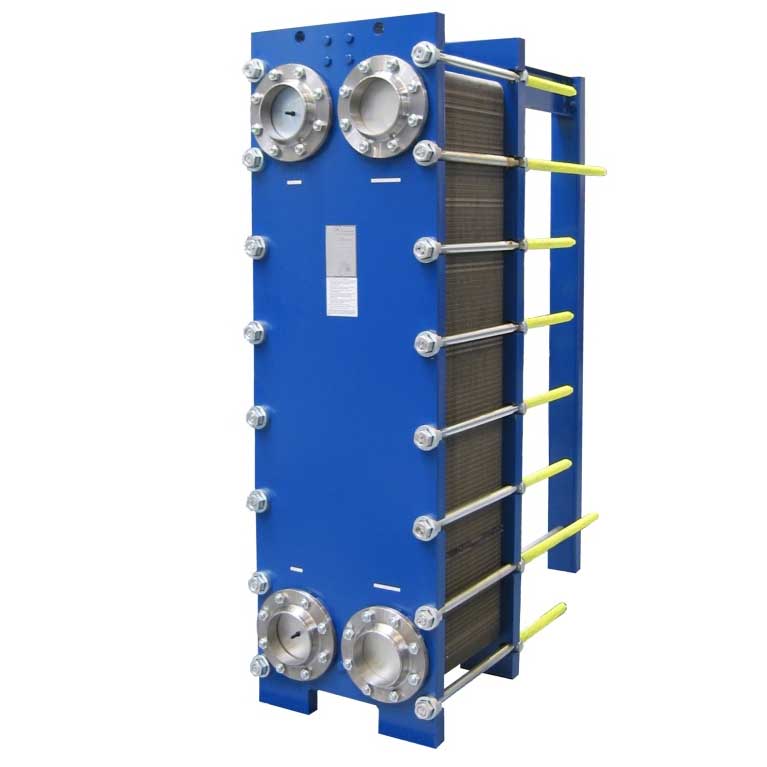

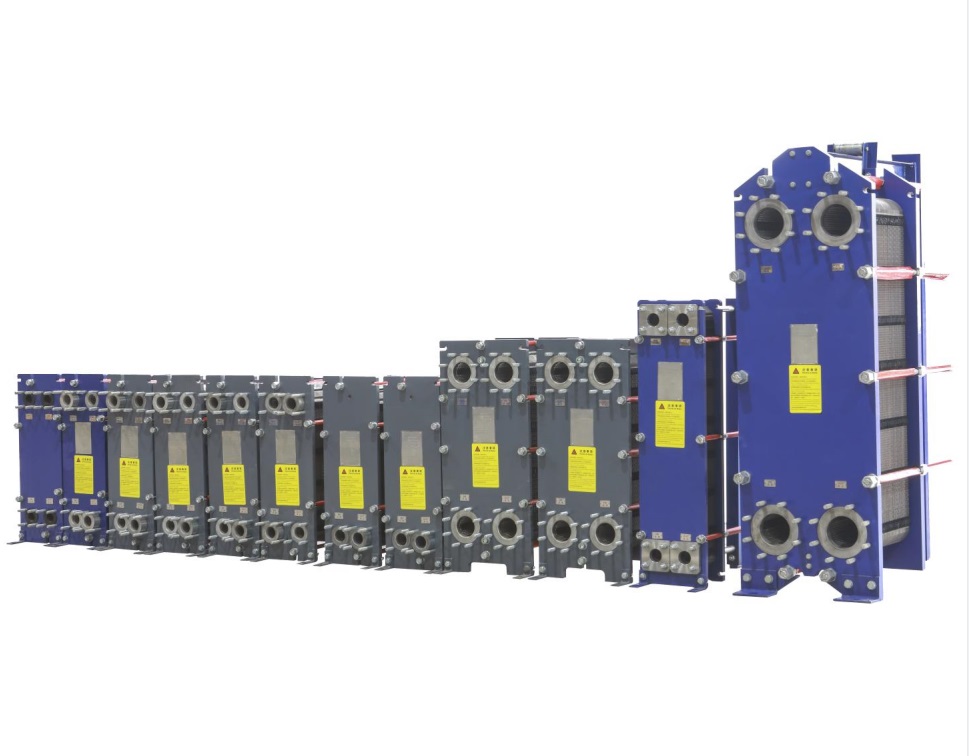

DGXT brand Plate Heat Exchanger

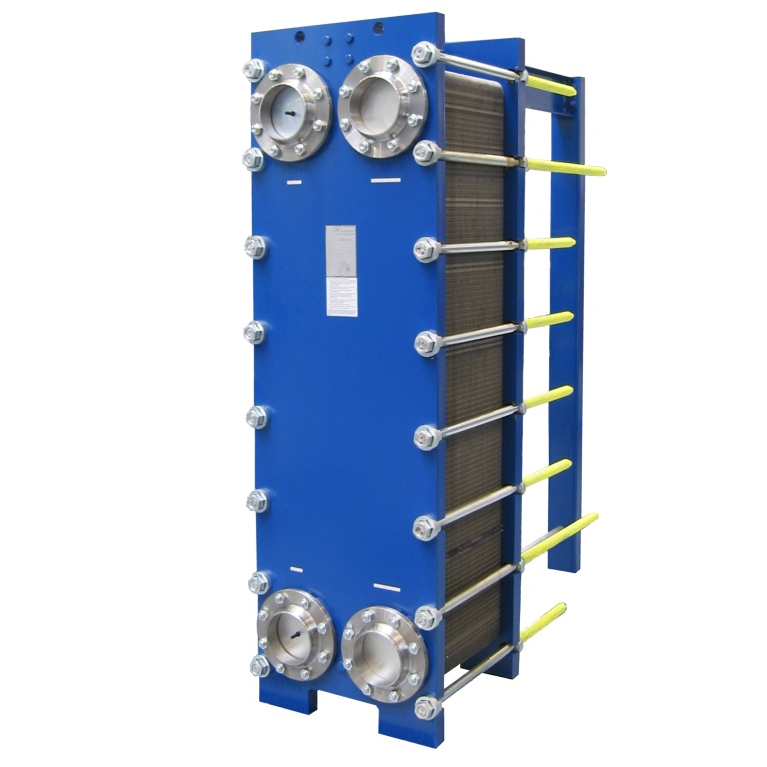

1.Frame material: commonly carbon steel or OEM other material

2.Port 2 kinds : EPDM rubber seleeve Gasket with pin or flange port

3.Plate material & thickness : Commonly AISI304/316/Ti plate 0.5/0.6mm

4.Gasket material : EPDM&NBR&FPM or others.(Most commly use is EPDM)

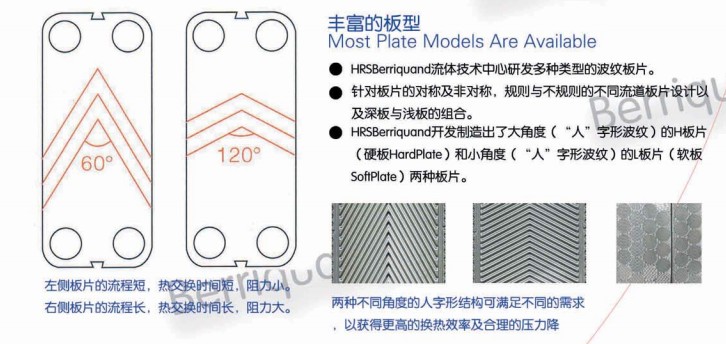

5.Plate models: H version (Hardplate 120 degree)or L version(Softplate 60degree)

6.we offer perfect after-sale service system for repair and training.

7.We offer professional technology selection service,free service to help choose Appropriate models for you.

8.our products are mainly to many countries,such as Pakisitan,India,Malaysia,Russia,Austrilia,Vietnam,Spain and so on.

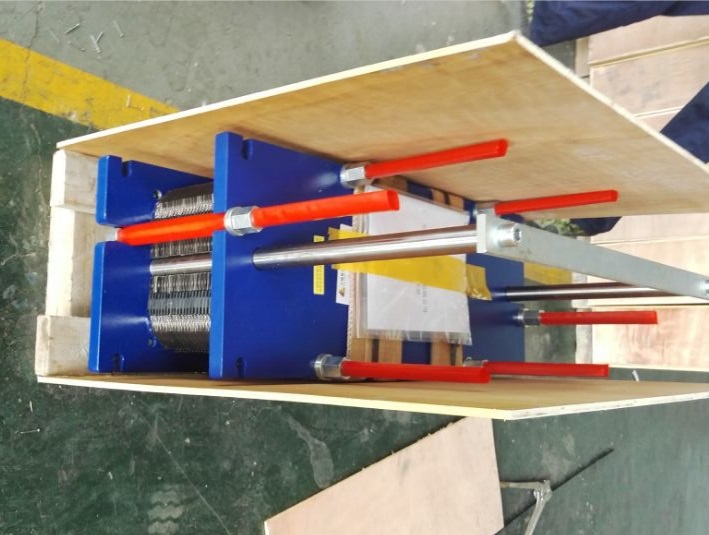

9.Packing size: standard export wooden packing or steel frame packing.

10.Weight and packing size:we offer specized Chinese and English calculation books.

10.Our MOQ:1pcs Nearby Port:Shanghai we do EXW,FOB,CIF

11.100% in advance before shipment.

Welcome to contract with us ,we are sincerely to cooperate with you,wish to built a long bussiness relationship.Cooperation and win-win!

Function: the heat exchanger is the equipment that transfers the heat of the hot fluid to the cold fluid, also known as the heat exchanger. Its main function is to ensure the specific temperature required by the process to the medium.

It can transfer heat between two or more fluids at different temperatures and more than two kinds of fluid, so that the heat transfer from higher temperature to the lower temperature fluid, so that the fluid temperature reaches the specified index of the process to meet the needs of the process conditions, and the heat exchanger is one of the main equipment to improve the energy utilization.

Features: plate heat exchanger has compact structure, small floor area and good heat exchange effect.

Application: widely used in oil industry, power station, solar photovoltaic, electronic industry, paper industry, textile industry, chemical, marine and engine, HVAC, food industry, edible oil processing, metallurgy industry and so on.

Features: compact structure, small area, good heat transfer effect, small pressure drop, many kinds of packing and good corrosion resistance, especially when it is easy to produce foam material and vacuum operation, it has its unique advantages.

Advantages: high heat transfer efficiency, large logarithmic temperature difference, light weight, small area, easy cleaning, and easy to change heat exchange area or flow combination, suitable for multiple medium heat transfer.

Application range of plate heat exchanger

Chemical industry:

1. Cooling formaldehyde, methanol and ethanol;

2, concentrate fermentation and refining;

3, condensation of methanol steam;

4, the heating and cooling of the alkaline solution and the electrolyte;

5, the cold of sulphuric acid;

6. Desalination process and heat recovery device.

7. Cooling resin;

Metallurgical Industry:

1. Direct or indirect primary cooler of coke oven;

2. The cooling of the furnace body and the water cold cover plate.

3. The furnace body of the ferroalloy furnace, the support of the electric plate and the cooling of the transformer;

4. The central chest, converter cooling and cover cooler of the oxygen top blown converter.

5. The lubricating oil and gear oil of strip hot rolling mill, cogging machine, strip cold rolling mill and thin strip rolling mill.

6. The cooling of electrolyte in tin and zinc production line.

7. Heating and cooling of closed circuit cooling system, washing liquid and electrolyte.

Petroleum Industry:

1, the heating and cooling of all kinds of oil.

2, the condensing and cooling of the top gas of the tower;

3. The cooling water system of the factory;

4. The treatment of acid water in the factory;

5. The offshore drilling platform is used for the heat recovery and cooling gas of the cooling water of seawater cooling or ethylene glycol crude oil cooling, desalting device, fresh water distillation, and dehydration of three glycoll.

Power industry:

1, central cooling system, turbine oil cooler;

2, diesel engine, generator cooler;

3, bearing, vacuum pump, pump cooler;

4, transformer oil, silicon rectifying pure water cooler;

Mechanical and electrical industry:

1. Cooling of hydraulic oil, lubricating oil and quenching oil;

2, the heating of the pickling pool and phosphating line.

3, emulsion cooling, rolling mill, extruder cooling;

Paper industry:

1, the cooling of black liquor and the condensation of wood pulp;

2. Heat recovery system: it is used to recycle steam, remove gas, heat machine pulp, mechanical pulp drifter, continuous boiling liquid, and export steam discharge liquid.

Pharmaceutical industry: heating, evaporation, condensation and sterilization cooling of all kinds of medicine and pure water.

Food industry: cooling, evaporation, crystallization, pasteurization and other processes in the processing of beverages, condiments, juice, wort and milk.

Cement industry: thin oil station, high temperature fan, air compressor, lubricating oil cooling;

Urban industry: District Central heating, central air conditioning, cold and hot air, domestic water, heating, etc.

Plate heat exchanger plate heat exchanger plate cooler type plate heat exchanger manufacturer Luoyang plate heat exchanger manufacturer Jiangsu plate heat exchanger manufacturer

Oil cooler manufacturer's oil cooler water cooler

Hydraulic oil cooler manufacturer quenching oil cooler lubricating oil cooler