Product Introduction

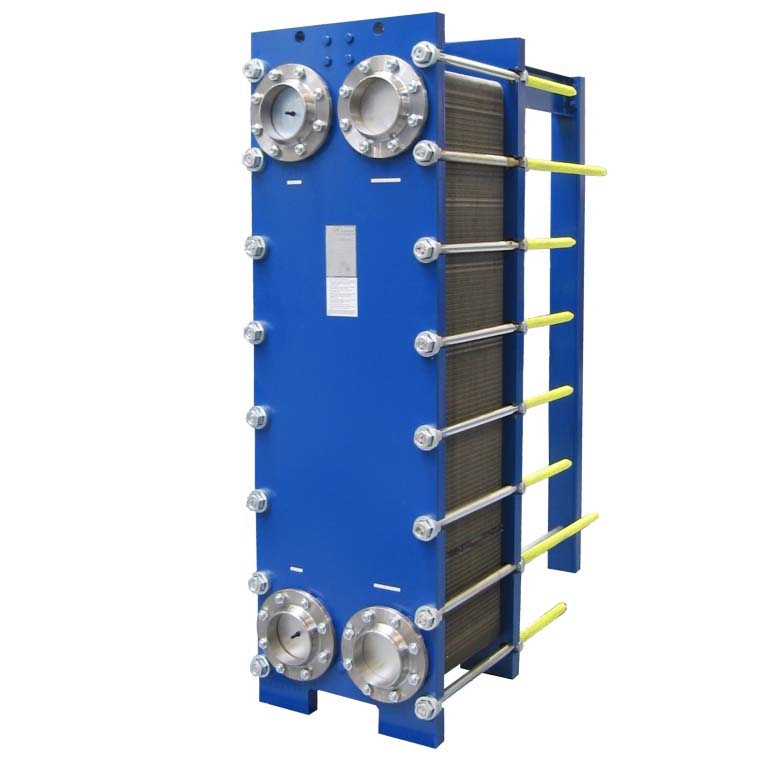

APV plate heat exchanger

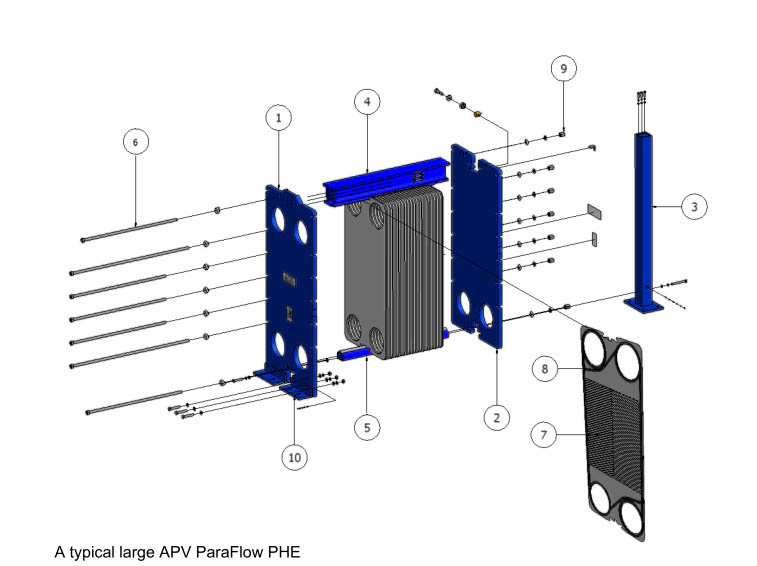

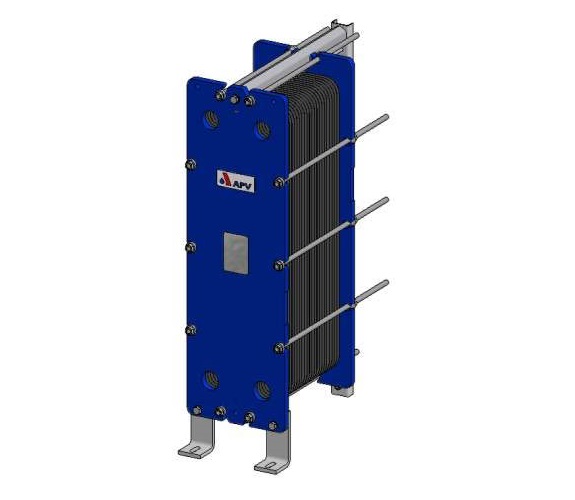

1.A typical large APV Paraflow PHE

Figure 1: Main Components of APV gaskets plate heat exchanger,industrial desian

1.Head for commection and clamping the plate pack

2.Follower for clamping the plate pack and additional connections

3.End support for ssupporting the top and bottom bars

4.Top bar for carrying and guilding the follwer and plate pack

5.Bottom bar for guiding the follower and plate pack

6.Tie bars for clamping the plate pack between head and follower

7.Flow plate

8.Flow gasket

9.Nut for tie

10.Footplate for securing the plate heat Exchanger to the base

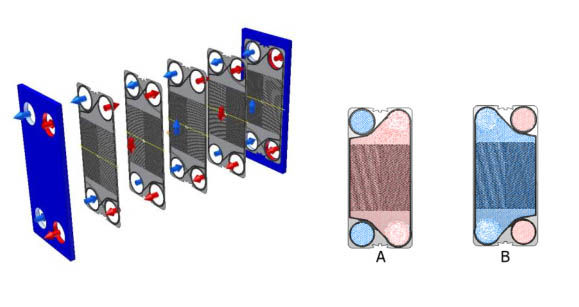

2.Operating Principle

2.1 standard design

The plate heat exchanger consists of a number of thin corrugated metal plates

The plate corrugations from flow channels for the heat exchanging fluids and provide strength to the compressed plate pack

The plates contain ports for fluid inlets,outlets and interconnect passages as required

Gaskets are attached to the plates,forming a seal between the heat exchanging fluids and the surroundings.(blue) enters at the bottom and the hot fluid(red)at the top.

2.2 Frame

The plate are clamped together to a predetermined dimension by the tie bars between two thick metal slabs:a stationary slab(head)and a mpveable slab (follower)

Connections for the fluid inlets and outlets can be made on either slab.

The plates are hung on the top bar and guided by the bottom bar. An end column supports the top and bottom bar ends

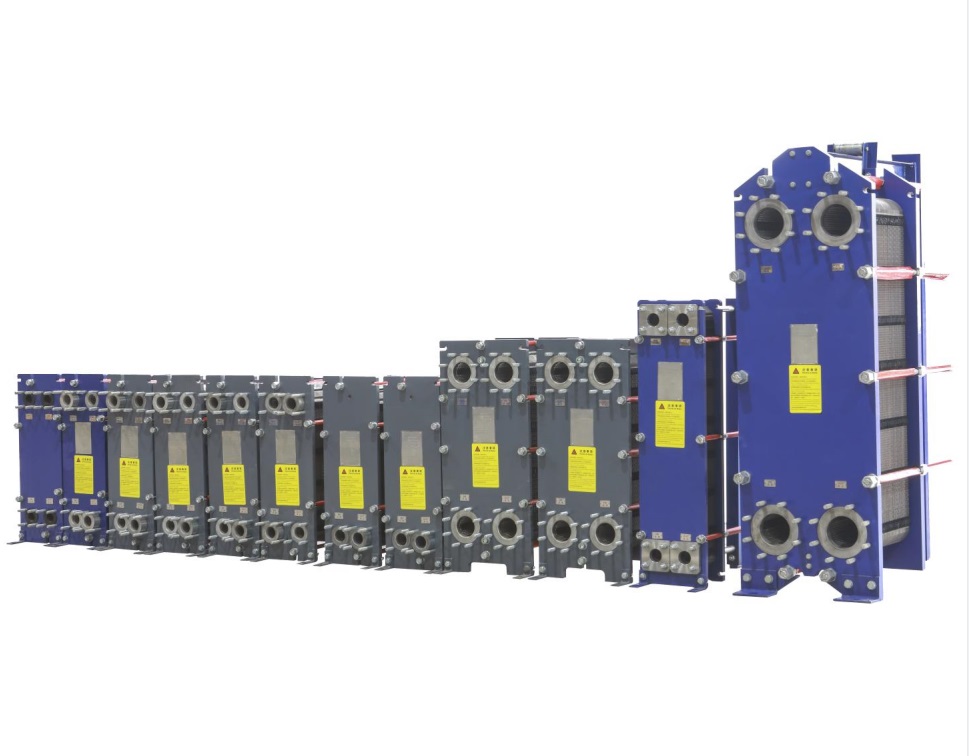

APV widly used type Product Model

|

Model |

Connection mm |

Flow Rate m3/H |

Pressure kg/m2 |

|

Area m2 |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| APV-T4 | 40.0 | 35 | 25.00 | 11 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| APV-SR2 | 50.0 | 55 | 25.00 | 60 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| APV-H17 | 65.0 | 85 | 25.00 | 60 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| APV-N35 | 80.0 | 130 | 25.00 | 180 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| APV-Q030 | 100.0 | 220 | 25.00 | 145 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| APV-SR6GH | 100.0 | 220 | 30.0 | 135 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| APV-LR4 | 100.0 | 220 | 21.00 | 115 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| APV-Q055 | 100.0 | 220 | 30.00 | 262 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| APV-SR6GL | 100.0 | 220 | 30.00 | 220 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| APV-Q080 | 100.0 | 220 | 30.00 | 386 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| APV-A055 | 150.0 | 500 | 30.00 | 380 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| APV-A085 | 150.0 | 500 | 30.00 | 420 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| APV-A145 | 150.0 |

|

30.00 | 650 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| APV-J060 | 200.0 | 850 | 30.00 | 365 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| APV-TR9GL | 200.0 | 850 | 30.00 | 285 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| APV-SR9 | 200.0 | 850 | 16.00 | 300 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| APV-J092 | 200.0 | 850 | 30.00 | 580 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| APV-TR9GN | 200.0 | 850 | 30.00 | 470 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| APV-J107 | 200.0 | 850 | 30.00 | 690 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| APV-TR9AV | 200.0 | 850 | 30.00 | 630 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| APV-TR9AL | 200.0 | 850 | 30.00 | 810 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| APV-J185 | 200.0 | 850 | 30.00 | 1300 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| APV-B063 | 300.0 | 1910 | 30.00 | 580 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| APV-B110 | 300.0 | 1910 | 30.00 | 1000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| APV-B134 | 300.0 | 1910 | 30.00 | 1200 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| APV-B158 | 300.0 | 1910 | 30.00 | 1400 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| APV-B205 | 300.0 | 1910 | 30.00 | 1500 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| APV-P105 | 350.0 | 2620 | 16.0 | 580 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| APV-P190 | 350.0 | 2620 | 16.0 | 1100 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| APV-SR23AO | 400.0 | 3200 | 18.0 | 1100 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| APV-SR23AN | 400.0 | 3200 | 18.0 | 1350 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| APV-SR23PV | 400.0 | 3200 | 18.0 | 1600 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| APV-SR23PD | 400.0 | 3200 | 18.0 | 1860 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| APV-SR23VA | 400.0 | 3200 | 18.0 | 2120 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| APV-SR23VO | 400.0 | 3200 | 18.0 | 2380 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| APV-SR23VN | 400.0 | 3200 | 18.0 | 2650 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|

|

|

|

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

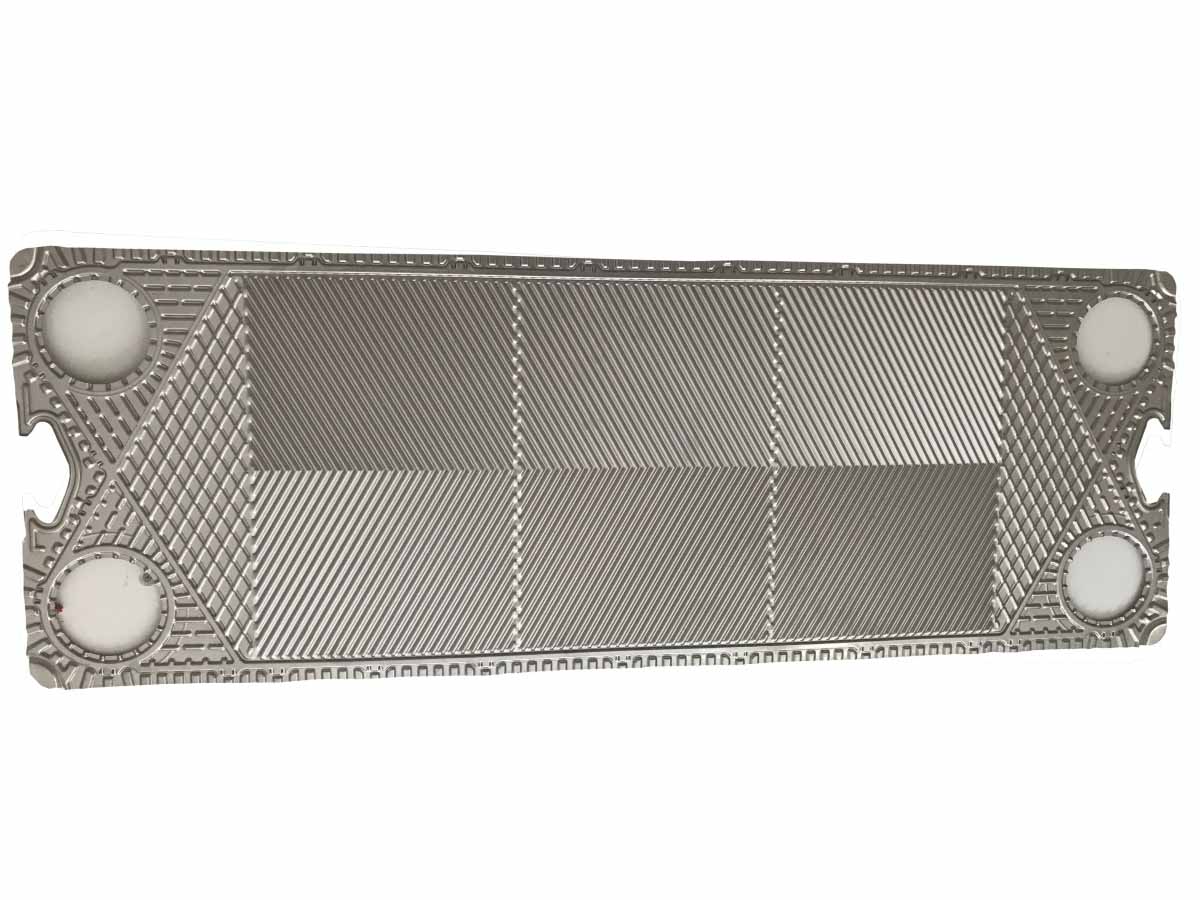

The plate of the APV plate heat exchanger has a plate locking function at four corners, which improves the pressure resistance of the plate and can be easily installed during maintenance. After the lock slots in the four corners are locked with each other, To ensure the reliable positioning of the plate heat exchanger.

Unique interlocking locationA unique feature of Paraflow is the interlocking gasket. A series of erect umbrella arches and umbrella shells ensure that all parts of the gasket are reliably supported in combination with the patented pressure tank. Provide plate and plate support strength for the sealing system. In compaction and operation, the alignment of the Paraflow beam is guaranteed by the erected ribs.

Embedded gasket

Paraflow can be equipped with APV's Parac doormat, which uses a mechanical connection method and can be fixed to the plate without bonding. Savings in time and money when disassembling gaskets, as no additional initial costs are required

The APV gasket is designed as a double seal to prevent the two fluids from mixing. When production is abnormal(for example, pressure shock) leaks, the fluid enters the dead zone formed by the double seal and is then discharged from the drain. This design makes the leak easy to find and can find the leak site.