Product Introduction

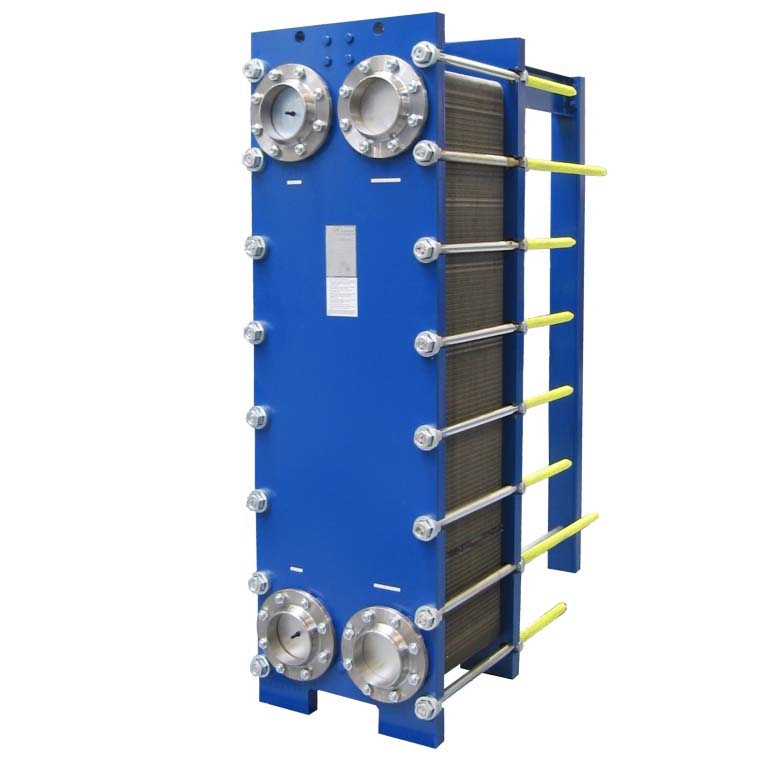

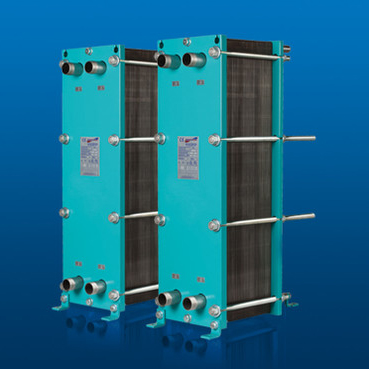

TB plate heat exchanger

Our company is specialized in the production of plate heat exchanger manufacturers, our factory production of plate heat exchanger adopts high quality plate material, high quality gasket material, high quality frame; Products before the factory, through a strict inspection and testing. Boost plate heat exchanger has a number of series, a variety of models, enough to meet customers 'different working conditions.

TB removable gasket plate heat exchanger TB plate heat exchanger for each working conditions of the first by the microcomputer selected plate number between the two thick steel plate clamping composition. Each plate has the same angle hole as the corresponding receiver, and the two fluids are alternately distributed in the respective flow channels between the plates. The two fluids always exchange heat energy under pure countercurrent conditions. Since Boyisite's patented die plate type is a thin fluid between the plates, it produces a turbulent state, forces the heat transfer, and reduces the thermal resistance of the liquid film. The heat transfer plate forms many support points, which is sufficient to withstand the pressure of the fluid.

| Model | DN | Flow Rate Max | Width | Height | Max surface |

|

|

mm | ㎡ | mm | mm | ㎡ |

| BT25-M | 25 | 8 | 140 | 380 | 1 |

| BT25-S | 25 | 8 | 200 | 621 | 1 |

| BT32-M | 32 | 14 | 180 | 490 | 3 |

| BT32-S | 32 | 14 | 200 | 896 | 5 |

| BT50-M | 50 | 45 | 320 | 930 | 37 |

| BT50-S | 50 | 45 | 300 | 994 | 40 |

| BT65-S | 65 | 72 | 430 | 1215 | 55 |

| BT100-M | 100 | 190 | 460 | 1084 | 100 |

| BT100-S | 100 | 190 | 480 | 1160 | 100 |

| BT100-S1 | 100 | 190 | 480 | 1755 | 200 |

| BT150-M | 150 | 390 | 650 | 1940 | 370 |

| BT150-S | 150 | 390 | 640 | 1450 | 370 |

| BT150-S1 | 150 | 390 | 640 | 1852 | 420 |

| BT200-M | 200 | 600 | 780 | 2260 | 410 |

| BT200-S | 200 | 650 | 790 | 1400 | 425 |

| BT200-S1 | 200 | 650 | 750 | 1700 | 425 |

| BT250-S | 250 | 650 | 750 | 2098 | 425 |

| BT250-S1 | 250 | 650 | 750 | 2500 | 425 |

| BT250-M | 250 | 900 | 920 | 2900 | 100 |

| BT300-M | 300 | 1400 | 1150 | 3100 | 1400 |

| BT300-S | 300 | 1400 | 970 | 1766 | 1400 |

| BT300-S1 | 300 | 1400 | 970 | 2176 | 1400 |

| BT350-S | 350 | 1400 | 1030 | 2806 | 1400 |

| BT350-S1 | 350 | 1400 | 1030 | 2176 | 1400 |

| BT500-S | 500 | 1800 | 1370 | 3560 | 1800 |

Application of Mechinox Plate and Frame Units

§ Water to Water Transfer

§ Hydraulic Oil cooling

§ HVAC – Domestic water heating

§ Steam to water heating

§ Pasteurization

§ Elution Cooling

§ General Process heating or cooling

§ Energy Recovery

§ Beer Wort Coolers

Particulars required for quotation

– Flow rates or heat load

– Temperature program

– Physical properties of liquids in question (if not water)

– Desired working pressure

– Maximum permitted pressure drop

– Available steam pressure